Aluminum 3D Printing Services

Wonder Tech’s success in aluminum comes from the keen eye and the experienced hand of the craftsmen who oversee our rigorous 3d printing process. Sophisticated systems ensure precise slm 3d printing aimed at protecting our customer’s products. Following the 3d printing process is an in-depth verification procedure that makes sure our work meets your parts specifications. We pride ourselves on our ability to meet the highest aluminum 3d printing standards while completing projects in a timely, cost-effective manner.Customers rely on us to slm 3d printing their most challenging projects, and we welcome it.

- Hold ISO 9001:2015 certification for aluminum 3d printing services.Provide fast and premium shipping of 3d printing aluminum parts or componentsglobally

- We has automated slm 3d printing machines for qualityproduction.

- Manufacture low to a high volume of 3d printing aluminum products

The Physical Properties Analysis Of 3D Printing Aluminum

Aluminum alloy is the most widely used non-ferrous metal structural material in the industry. It is an alloy material casted based on aluminum and added with silicon, iron, copper, manganese, magnesium, chromium, zinc, titanium and other metals.

Aluminum alloy has low density, but relatively high strength, close to or exceeding high-quality steel, good plasticity, can be processed into various profiles, and has excellent electrical conductivity, thermal conductivity and corrosion resistance. The following is the physical property analysis of aluminum alloy printing:

| performance | standard test | unit | value |

|---|---|---|---|

| production density | g/cm3 | 22.65 |

XY direction

Printing performance

| tensile strength Yield | ISO6892-1 | MPa | 430+30 |

| Strength | ISO6892-1 | MPa | 270+30 |

| Elongation | ISO6892-1 | % | 3+1 |

| After Break Hardness | ISO6507-1/ISO6508-1 | HV/HRC | 140+20 HV5/15 |

XY direction

Heat treatment performance

| tensile strength Yield | ISO6892-1 | MPa | 430+30 |

| Strength | ISO6892-1 | MPa | 270+30 |

| Elongation | ISO6892-1 | % | 6+1 |

| After Break Hardness | ISO6507-1/ISO6508-1 | HV/HRC | 75+20 HV5/15 |

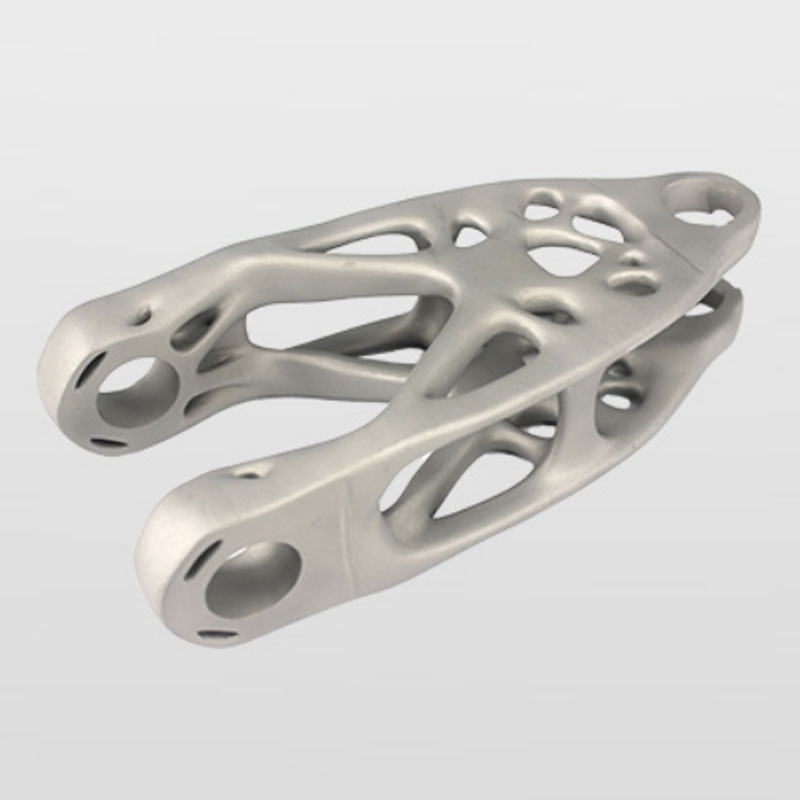

The 3D Printing Aluminum alloy Alsi10Mg material can be used in the selective laser melting (SLM) forming process to manufacture parts that are not limited by geometric shapes, shorten the product development and manufacturing cycle, and can quickly and efficiently manufacture small batches of complex parts.

The Appilcations And Case Studies Of Aluminum 3D Printing

The main application fields of aluminum alloy are aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industry.

The Characteristics Comparison Of Aluminum

| parameter | print status | Heat Treatment State |

|---|---|---|

| ultimate tensile strength | 460+20MPa(XY) | 345+10MPa(XY) |

| ultimate tensile strength | 460+20MPa(Z) | 350+10MPa(Z) |

| Yield Strength | 270+10MPa(XY) | 230+15MPa(XY) |

| Yield Strength | 240+10MPa(Z) | 230+15MPa(Z) |

| Young’s Modulus | 75+10GPa,(XY) | 70+10GPa,(XY) |

| Young’s Modulus | 70+10GPa,(Z) | 60+10GPa.(Z) |

| Elongation At Break | 9+2%(XY) | 12+2%(XY) |

| Elongation At Break | 6+3%(Z) | 11+2%(Z) |

| Hardness | 119+5HBW | 119+5HBW |

| Element | Si:9~11; Fe:<0.55; Cu:<0.05; Mn:<0.45; Mg:0.2~0.45; Ni:<0.05; Zn:<0.1; Pb:<0.05; Sn:<0.05; Ti:<0.15; | Si:9~11; Fe:<0.55; Cu:<0.05; Mn:<0.45; Mg:0.2~0.45; Ni:<0.05; Zn:<0.1; Pb:<0.05; Sn:<0.05; Ti:<0.15; |

| Forming Precision | plus or minus 100um | plus or minus 100um |

| Application Direction | The closest brand in China is ZL104 cast aluminum alloy. The material has low density and good corrosion resistance. It is mainly used in aerospace and automotive industries with lower strength requirements for weight reduction, as well as heat dissipation components in automotive and electronic industries. | The closest brand in China is ZL104 cast aluminum alloy. The material has low density and good corrosion resistance. It is mainly used in aerospace and automotive industries with lower strength requirements for weight reduction, as well as heat dissipation components in automotive and electronic industries. |