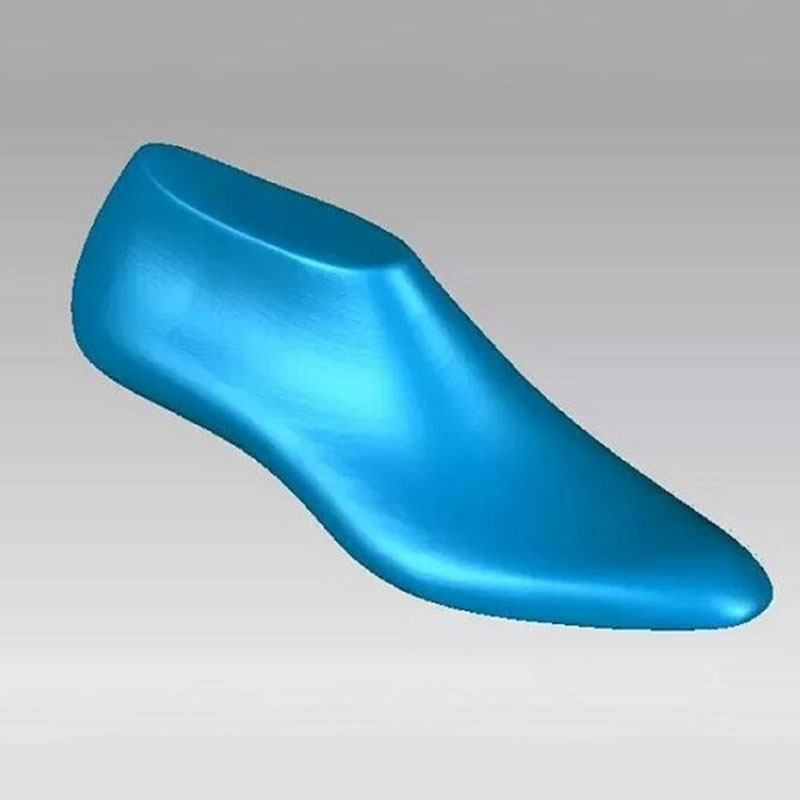

The sole mold is a kind of tool used to make or copy the finished shoe sole, and its manufacturing cycle and quality will affect the competitiveness and replacement of…

3D Scanning is now more popular than ever, and businesses all over the world are embracing it to boost productivity, eliminate unnecessary costs, and create new and exciting products and services.Compared to many other methods of data capture, it is one of the fastest, safest, and most cost-effective ways of achieving high-quality 3D models of all kinds of objects.

When accuracy and detail are paramount on your design project, Wonder Tech’s 3D scanning services provide you with access to the most advanced laser scanning technology, empowering your team with the ultimate tool for digitally rendering physical objects found in the real world.

With over 20 years of experience in 3D SCANNING SERVICES, Wonder Tech utilizes the newest technologies providing the most accurate and highest resolution 3D scan data in the industry. At Wonder Tech, we have a skilled in-house design team dedicated to to digitize virtually any physical object from cell phone components to entire aircraft. In addition to 3D scanning, Wonder Tech specializes in reverse engineering and 3D part inspection. Whether you need to remanufacture obsolete parts, design aftermarket components, or troubleshoot part geometry,Wonder Tech can help. You can send your parts to us, or we can come to you and scan onsite. Learn more about 3D scanning services pricing.

Make Your 3D Scanning Step By Step

- Send us a picture of the object that you’d like to be 3D scanned. It will give us an idea if 3D scanning is right for your project.

- After we get an idea of your project requirements, we’ll send you a rough estimate of how much it costs.

- Once approved, you can mail us the object that you like to be scanned.

- After we have all the requirements including your object, we can start 3D scanning. It will take 2-3 days depending on the complexity of the project. We do multiple iterations and CAD modeling changes to make sure that the 3D model matches the original work.

- Once the model is finished, we’ll send you the 3D files and you have the option to have it 3D printed. We can make it larger, smaller or true to scale — whichever you want it.

For both seasoned scanning professionals and complete novices, the solutions offered are fast and easy.

Quality 3D Scanning Services To Boost Your Business

Wonder Tech is a trusted and well-known china 3d scanning manufacturer with reliable and durable products for your business needs. We feature different 3d scanning process to boost your business and increase your sales.

Equipment We Use

Wonder Tech utilizes several portable 3D scanners for both high-accuracy and long-range laser scanning. We service customers throughout global and have resources in USA, JAPANESE, Taiwan and more.

With minimal time spent using portable, light, and intuitive machines, our professional scanners ensure your data is effortlessly captured, your workflow improved, and your results accurate each time.

Please contact us to learn more about 3D scanning technology, 3D scanning methods, 3D scanning limitations, 3D laser scanning services, 3D building scanning services, 3D scanning equipment, and structured light 3D scanning. 3D scanning services near me.

3D scanning services : key specs

3D laser scanning is used in many fields such as industrial design, reverse engineering, robot navigation, medical inspection, criminal identification, heritage conservation, film production and game creation. 3D laser scanning technology, also known as real-world replication technology, is a technological revolution in the field of surveying and mapping following GPS technology. It is a breakthrough from the traditional single point measurement method and has the unique advantage of high efficiency and accuracy. 3D laser scanning technology can provide 3D point cloud data of the scanned object surface and can therefore be used to obtain high precision and high resolution digital terrain models.

| 3D Point Accuracy | From 0.02 mm |

| 3D Resolution | From 0.1 mm |

| Object Size | From a fingerprint up to an industrial building |

| Full Color Scanning | Yes |

| File Format Of 3D Model | All popular formats, including OBJ, PLY, STL, and WRL |

Wonder Tech’s 3D Scanning Case Studies

With two decades of offering on-demand production and rapid prototyping services, Wonder Tech is the perfect partner for bringing ideas to life. We have a wide range of processes and materials to choose from, each with its own benefits and applications.If you have this requirement, please contact our professional team at [email protected] or contact us by visiting our website, we will provide you with a quote for free for the first time. Upload a model and we’ll do the rest!

3D Scanning And Printing Modified Motorcycle Model

This is not the first time BMW has entered into a relationship with 3D printing, 3D scanning technology. A few months ago, they used the technology to build thumb supports…

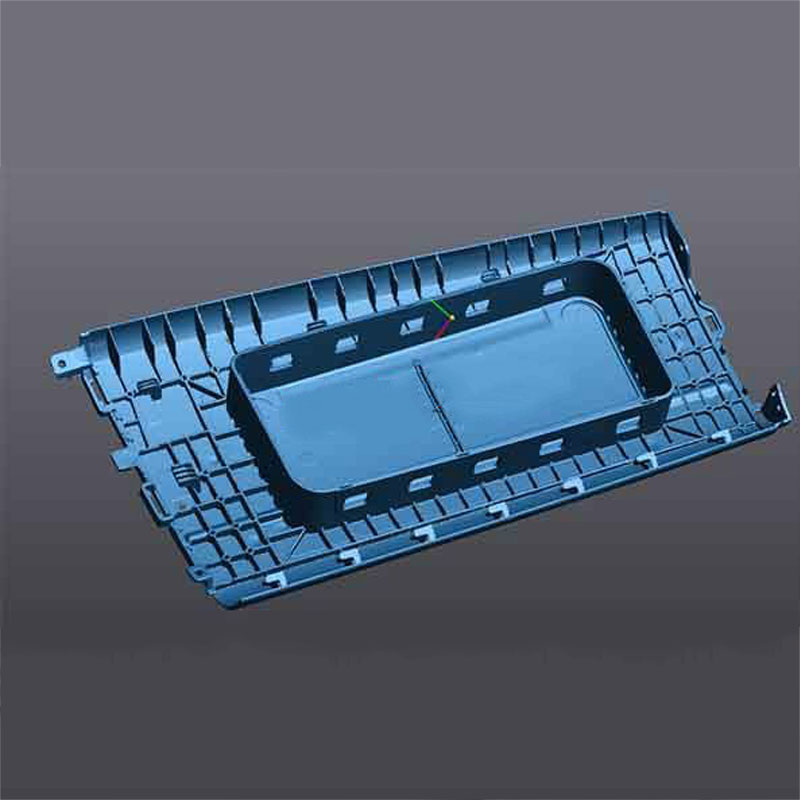

3D Scanning Car Modification Accessories

Car modification is not only favored by consumers in the direction of appearance, but also the demand for improving performance and practicality is also increasing. Being able to quickly and…

3D Scaning Buddhist Temple Arch At Wutai Mountain

In recent years, we have seen that 3D scanning technology has been used to help protect many of China’s cultural heritage. Now, let’s take a look at the handheld 3D…

3D Scanning Automotive Exterior

An essential part of the process of modifying the exterior of a car is to obtain data on the car’s curves in order to create a perfect fit.There are three…

Scaling Bronze Sculpture

Sculpture company wanted to equivalently scale down an existing sculpture and turn it into a scaled-down version as a souvenir. However, traditional sculptures are not available electronically and direct modelling…

Desert Kettle Film TV Prop Model

The film and television prop model is designed through the pictures provided by the customer, based on the contents of the pictures and the size of the model for three-dimensional…

Custom Stamps Via Images

The client wanted a customised seal based on a manuscript. Once the manuscript was obtained the lines were first extracted, the vector lines were entered into the modelling software and…

3D Printing Sports Car Parts

Aston Martin sports car with damaged right-hand side corner cladding piece, an expensive sports car, had to be matched with a high-tech machining method. Based on the left-hand side of…

What Is 3D Scanning

We often see the word ‘3D’ in our daily lives, such as 3D movies, 3D animation, 3D printing, 3D scanning and so on. I’m sure we’ve all heard of the first two, but 3D scanning is still an unfamiliar word to most people. So what is 3D scanning?

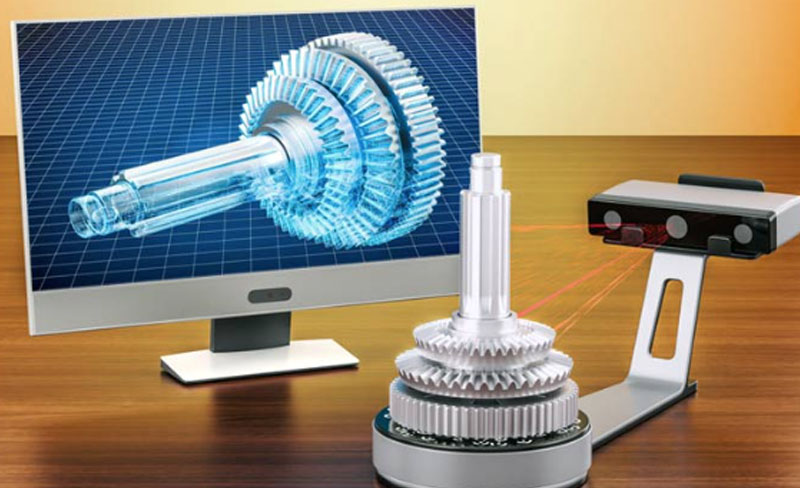

Imagine that you photograph any object in the real world and then obtain a digital model of it in a matter of minutes. The principle can be likened to that of a camera taking a picture, the difference being that the camera captures colour information, whereas 3D scanning captures location information. The importance of 3D scanning lies in its ability to convert the three-dimensional information of a physical object into a digital signal that can be directly processed by a computer, providing a convenient and fast means of digitising the object.

With 3D scanning, you definitely need to get in touch with a 3D scanner. And what is a 3D scanner? What is the main role played by this “magic tool”?

In fact, there are many devices that can be called 3D scanners. We can refer to devices that scan the physical world with lasers, rays or X-rays to create dense point clouds or polygonal meshes as 3D scanners. They are also known by many other names, such as 3D digitisers, laser scanners, white light scanners, industrial CT, or LIDAR and so on. What these devices have in common is that they construct geometric information about the surface of an object by taking countless measurements. 3D scanners are scientific instruments that are used to detect and analyse the shape and appearance of objects or environments in the real world. The information gathered is used to perform 3D reconstruction calculations to create data models of actual objects in the virtual world. These models are used for a wide range of purposes, industrial design, reverse engineering, medical information, film production …….

The Advantage Of 3D Scanning

Regardless of the industry, 3D scanners can be used to their advantage in the work process. Because of their “high accuracy, high efficiency and high resolution”, 3D scanners can be used in the manufacturing industry to improve efficiency and reduce production costs. The number of practical applications for 3D scanners is gradually increasing, with more industrial applications at the moment and the benefits of 3D scanners to be seen everywhere in our lives in the future.