3D printed titanium alloy pen. The material used is titanium alloy. The flowers are integrally formed with a hollow design, with exquisite design and exquisite workmanship. The surface of the…

3D Printing For Medical Device

The next-generation precision medicine industry is a strategic emerging industry that China is focusing on developing. China has been introducing 3D printing technology into the medical industry since the early 1990s. After nearly 30 years of development, with the gradual integration of 3D printing technology and the medical industry, 3D printing technology has successfully ventured into the fields of oral prosthetics, customised prosthetics, surgical guides and medical implants. In the future, it may enable the printing of active tissues such as cells, and even complete the printing of complex organs such as complete kidneys, livers and hearts.

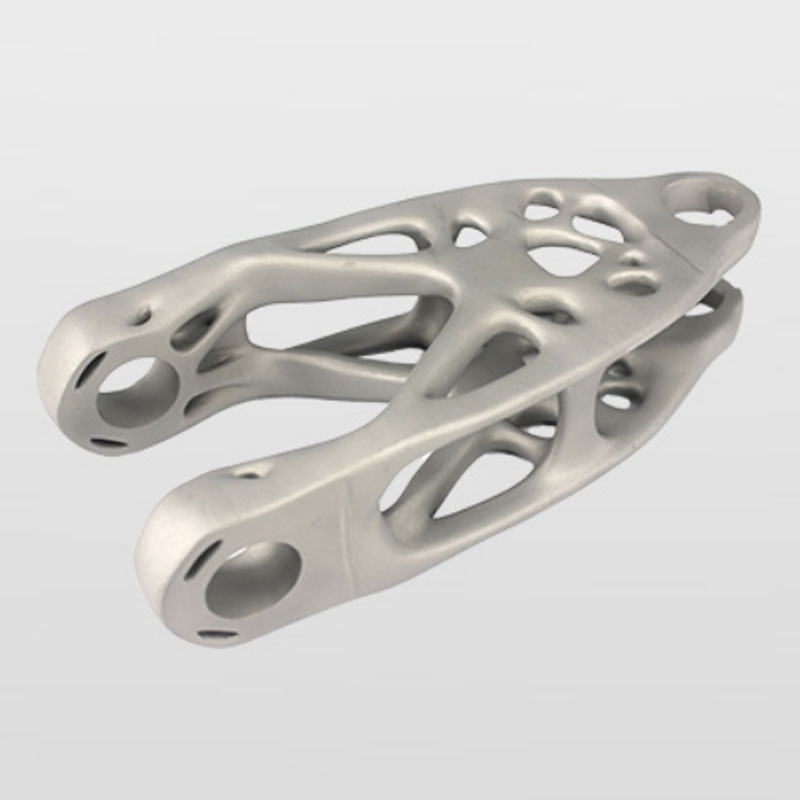

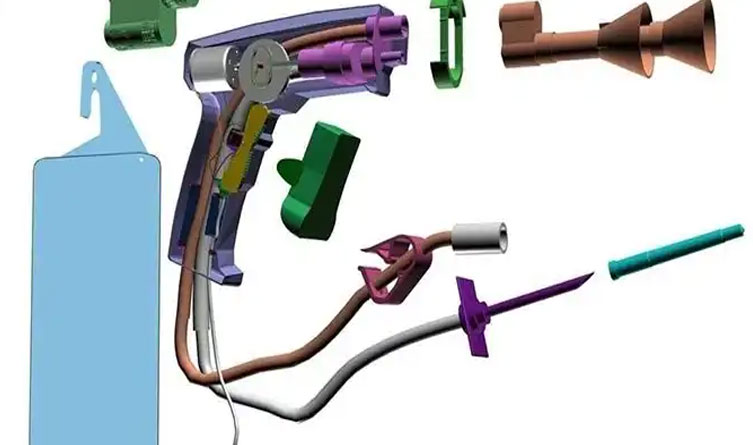

The potential of metal 3D printing technology in the medical device sector has gone beyond prototypes to undertake the manufacturing of complex surgical instruments.

For example, in surgery to repair an ACL injury in the knee, the surgeon first has to remove the remaining ACL and then accurately replace it with the graft ligament. To ensure that the procedure is precise and minimally invasive, the surgeon needs to use a precise and special surgical tool.

The nickel-chromium-iron alloy used to make this tool is a difficult material to machine, which makes it difficult, time-consuming and costly to manufacture using traditional machining methods. In this case, the use of metal 3D printing technology is more suitable.

One-stop Medical 3D Printing Services

Wonder Tech is dedicated to providing game-changing solutions- high-performance solutions and faster Medical Device 3D Printing services with flexible designs.

We have brought nearly 20 years of materials and manufacturing expertise to every layer of your 3D products to help you in unlocking every dimension of 3D printing techniques.

The Some Case Studies Of Metal 3D Printing

Wonder takes pride in offering fast, high-quality, tailored projects parts for leading companies in Medical parts industries. Our experience and ISO and IATF certifications ensure quality in every project. We understand the demands of Medical industry and work with you to ensure they are met and exceeded.Whether you need new product development and validation, custom tooling, etc., Wonder Tech can meet your needs.

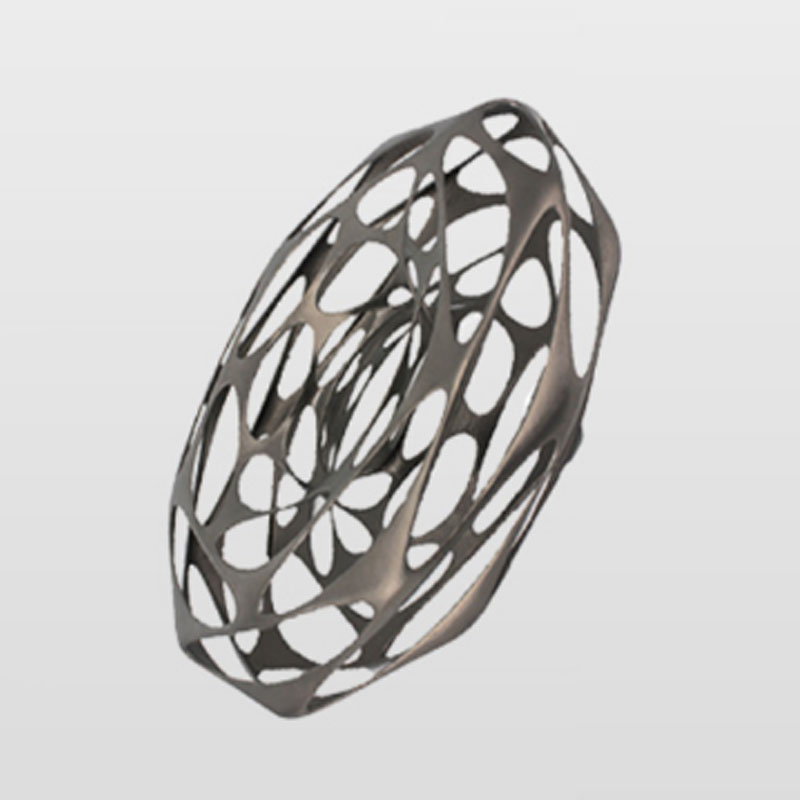

3D Printing Titanium Alloy Lampshade

3D printed titanium alloy lampshade. The integrated manufacturing of thin-walled, large-sized, hollowed-out and special-shaped curved surface structures has been realized. The process performance is stable, the surface quality is high,…

3D Printing Western Zhou Dynasty Dake Ding

The full name of the Dake Ding is the Dake Ding of the Western Zhou Dynasty, also known as the Ke Ding and the Shanfu Ke Ding. It is an…

3D Printing Formula Automotive Connector

Realize the precision forming of aluminum alloy parts, the overall size consistency is good, the processing cycle is short, which is conducive to the rapid verification of new products; the…

3D Printing Automotive Rocker

3D Printing Automotive Rocker realizes the precision forming of high-strength steel parts, and 3D printing integrated forming, which reduces the weight by 23% compared with the original design; no post-processing…

3D Printing Arc Welding Table Legs

This structure adopts arc additive manufacturing technology: (WAAM) one-time overall preparation and forming, the structure is a spatial topology structure, the spatial envelope size is 550550900mm, and the minimum hanging…

3D Printing For Prosthodontics

The digital scan quickly and accurately captures data from the patient’s mouth, providing a more precise fit for the orthopaedic instruments associated with dentistry and orthopaedics; at the same time, 3D printing technology provides patients with highly personalised dental implants and dental moulds.

3D Printing For Rehabilitation Aids

Functional integration, lightweight design, rapid customisation, improved wearing and wearing comfort and aesthetics.

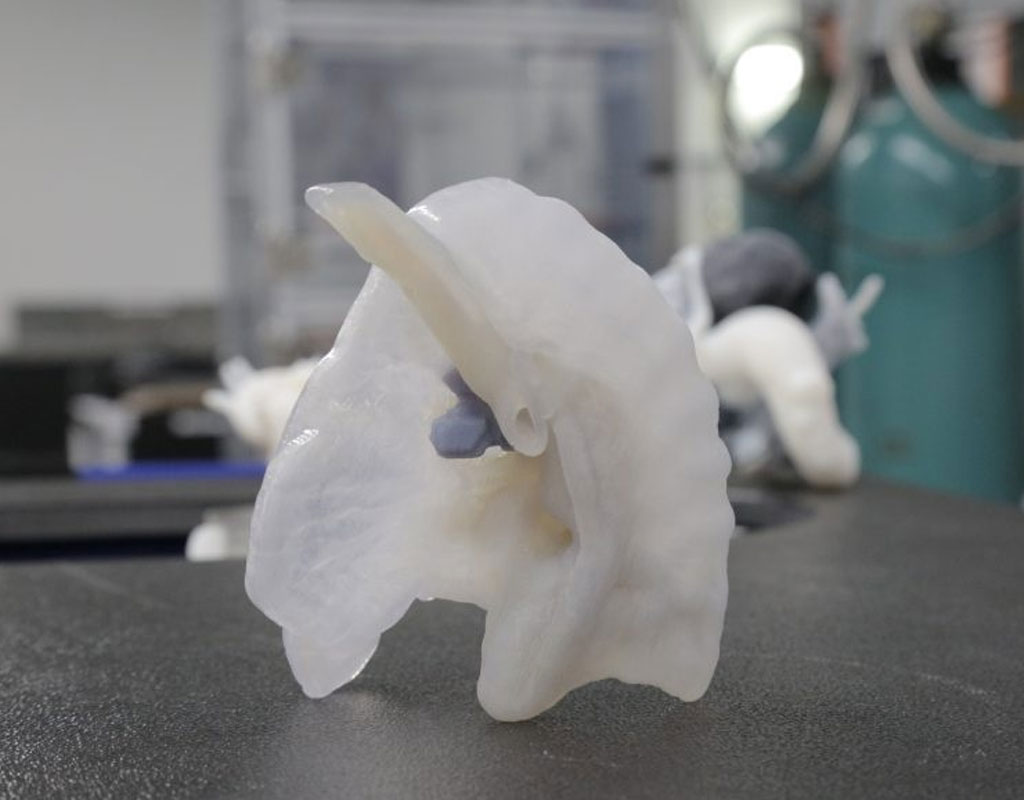

3D Printing Pre-Operative Models, Surgical Guides

Quickly and accurately printing out models of relevant tissues or organs before surgery facilitates doctor-patient communication and medical planning, and also increases the success rate of surgery.

3D reconstruction of the human body from CT images and 3D modelling to create surgical guides.

New Product Development For Medical Devices

All kinds of test and assembly parts can be manufactured quickly and economically, replacing the high costs and long lead times of traditional mass production in moulds.