Mould Steel 3D Printing Services

Mold steel performance in the process of manufacturing is particularly important, at this stage the industrial level of Europe and the United States is still in the world’s leading position, many high-grade mold steel and other mold materials must still be imported, and domestic mold steel can not fully meet the needs of the domestic mold industry.

Wonder Tech has introduced this imported mould steel features: compared with domestic mould steel, the tensile strength after heat treatment is slightly better.

- Hold ISO 9001:2015 certification for 3d printing mould steel services.Provide fast and premium shipping of 3d printing mould steel parts or componentsglobally

- We has automated slm 3d printing machines for qualityproduction.

- Manufacture low to a high volume of 3d printing mould steel products

The 3D printing mould steel material can be used in the selective laser melting (SLM) forming process to manufacture parts that are not limited by geometric shapes, shorten the product development and manufacturing cycle, and can quickly and efficiently manufacture small batches of complex parts.

The Appilcations Of Mould Steel 3D Printing

As far as the material itself is concerned, Imported mould steel has high strength and corrosion resistance, and can be dropped to low temperature in a wide temperature range.Imported Mould Steel also has good resistance to chloride corrosion.Main application directions:

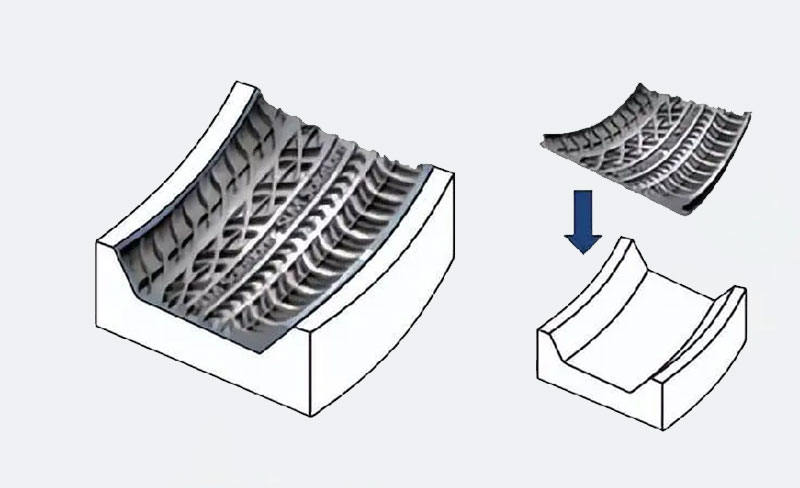

- Mould and die manufacturing (e.g. with shaped cooling runner mould cores).

- Industrial parts production (e.g. functional prototypes, small-scale production parts, customised parts and spare parts)

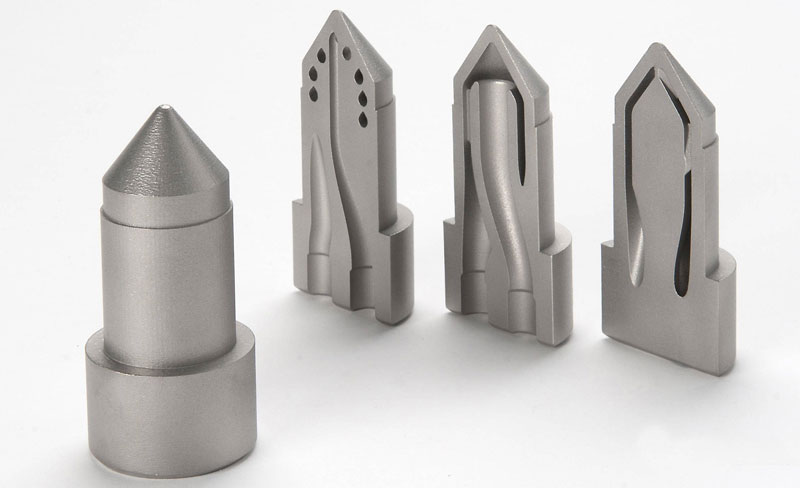

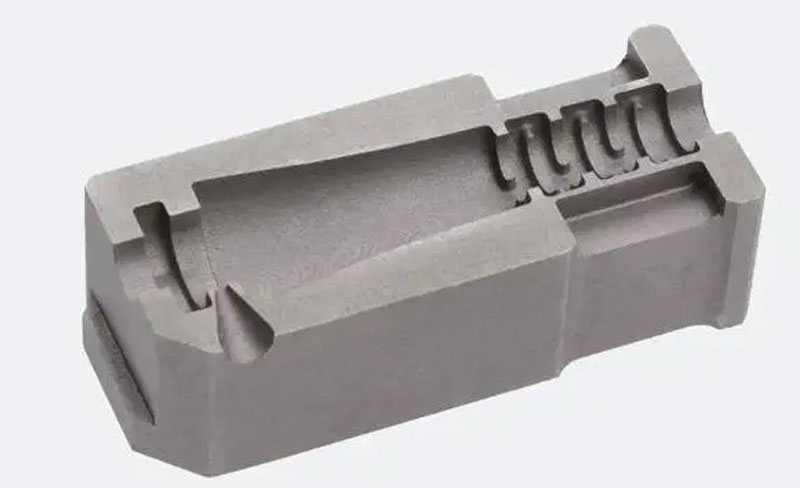

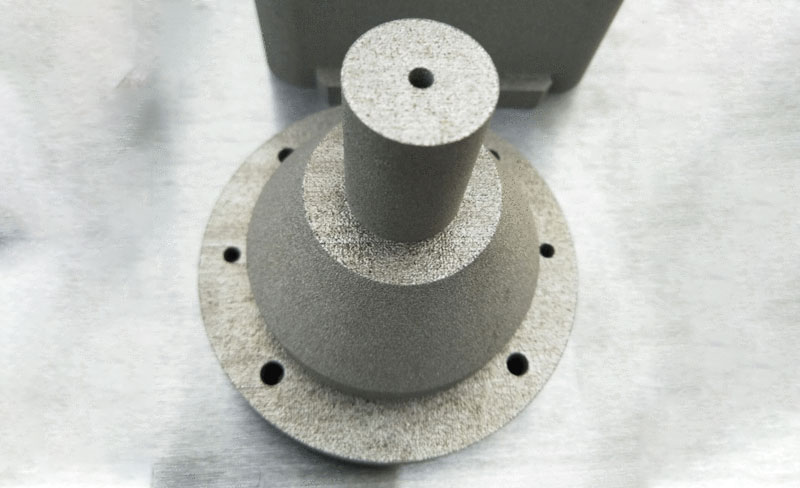

The Case Studies Of Mould Steel 3D Printing

Some examples of 3D printed mould steel are shown below.

The Characteristics Comparison Of Imported Mould Steel

| performance | standard test | unit | value |

|---|---|---|---|

| production density | g/cm3 | >8.00 |

XY direction

Printing performance

| tensile strength Yield | ISO6892-1 | MPa | 1100+100 |

| Strength | ISO6892-1 | MPa | 1050+100 |

| Elongation | ISO6892-1 | % | 10+4 |

| After Break Hardness | ISO6507-1/ISO6508-1 | HV/HRC | 32+2 HRC |

XY direction

Heat treatment performance

| tensile strength Yield | ISO6892-1 | MPa | 2050+100 |

| Strength | ISO6892-1 | MPa | 1990+100 |

| Elongation | ISO6892-1 | % | 4+2 |

| After Break Hardness | ISO6507-1/ISO6508-1 | HV/HRC | 53+3 HRC |