3D Printing Toughening Resins

Imported toughened resin material enables the production of accurate, highly detailed parts with a simple design and easy processing. It looks and feels virtually indistinguishable from traditional thermoplastics, making it ideal for the construction of parts and prototypes for functional testing applications, thus saving time, money and materials in the product development process.In the cases produced by Wonder Tech, the main applications for such printed parts are.

- Models of remote control housings.

- Models with snap assemblies.

- Models of water dispenser housings.

- models of mobile phone cases.

- Models of buttons, etc.

The 3D printing Imported Toughening Resins material can be used in the SLA 3D Printing forming process to manufacture parts that are not limited by geometric shapes, shorten the product development and manufacturing cycle, and can quickly and efficiently manufacture small batches of complex parts.

The Advantages And Disadvantages Of 3D Printing Imported Toughening Resins

- Advantages: easy to clean and finish, high strength and durability, precise and dimensionally stable high detail.

- Disadvantages: unsuitable for use as a final product, easily soiled, slightly laminated surface in contrast to 8000 resin, slightly yellowish colour, easily deformed or softened in case of thin walls.

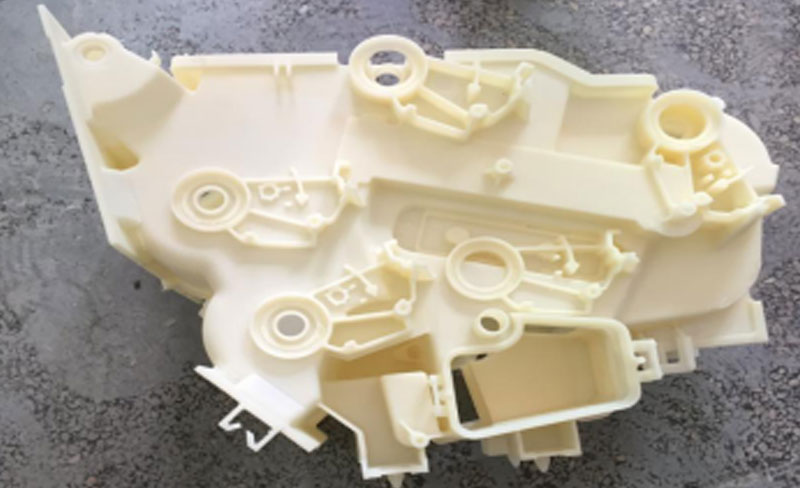

This car accessory shell is printed on imported toughened resin, and after a long period of storage, the surface gloss deteriorates and the colour becomes slightly yellow. It is not recommended to use this material if you have long storage and colour requirements.

Also, as mentioned above, this material becomes softer and more brittle in the thin walled areas, making it easier to damage, so avoid using this material for thin walled or small prints.

If you don’t know much about the properties of the material you can consult our online customer service and we will have a technical engineer available to help you choose the right material solution for your needs.

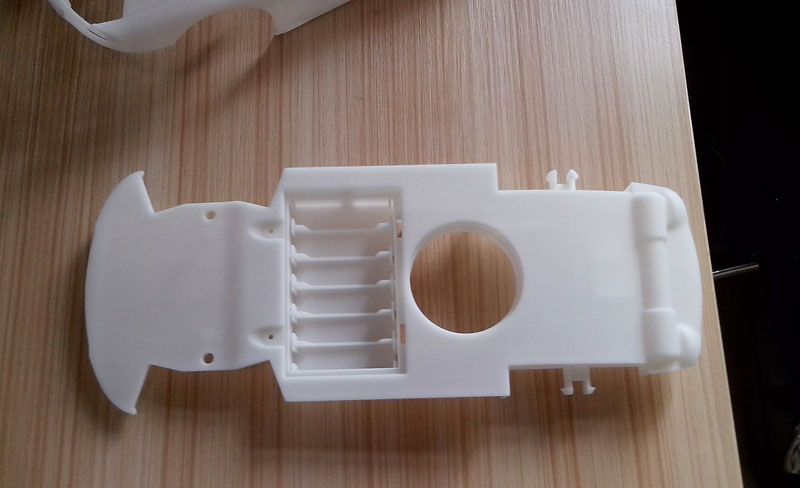

The Case Studies Gallery Of Imported Toughening Resins 3D Printing

Due to the fluidic nature of the resin and the precision of the laser, the surface of the print often has a high degree of smoothness and is often used as a cosmetic verification part. The diagram below shows some examples of this resin material being used for the verification of the appearance of hand boards. The imported toughened resin also performs well when producing such highly complex prints, with a very fresh and smooth structure.

The Characteristics Comparison Of Imported Toughened Resin

Compared to ordinary photosensitive resin materials, imported toughened resin materials have a more outstanding performance in terms of toughness, this outstanding physical properties make the printing of many functional parts and assemblies will give preference to this material, in the process of assembly and test samples of its not easy to damage can better test the function of the printed parts.

Below is a list of the physical properties of our imported toughened resins, which can be used for reference.

| Performance | standard test | unit | value |

|---|---|---|---|

| Viscosity | cps @ 3o”c | 380 | |

| Critical Exposure | mJ/cm2 | 9.3 | |

| Young’s modulus | ASTM D638 | MPa | 2.965 |

| Tensile strength | ASTM D638 | MPa | 57 |

| Elongation | ASTM D638 | 0.11 | |

| Notched Impact Strength | ASTM D256 | J/m | 39 |

| Heat deflection temperature @0.46 Mpa | ASTM D648 | ℃ | 52″ |

| Heat deflection temperature @1.81Mpa | ASTM D648 | ℃ | 49″ |

As we can see by comparing the imported white resin materials we have mentioned previously, this toughened resin material has a more significant increase in tensile strength, elongation and impact strength.

Compared to the price of ordinary imported resins, the price range of imported toughened resins with more physical properties is not too high, in the range of 0.85-1.1 RMB/g. For customers who require toughness, this material is undoubtedly very cost-effective.Wonder Tech Is Committed To Providing You With The Most Comprehensive Range Of Materials Available, To Getting You The Best Discounts While Maintaining Quality, And To Choosing The Best Match For Your Material Printing Solution.