3D Printing Imported White Resin

The photosensitive resins used in 3D printing are initially liquid and are cured by the irradiation of UV light. There are many options available for photosensitive resin materials, from colour, transparency to hardness. Photosensitive resins are one of the most commonly used materials for 3D printing and the predominant process for 3D printing resins is SLA.

The photosensitive resins used in SLA are by far the most popular printing materials, these materials offer crisp print detail, high quality surface moulding, moderate prices and a wide range of options. SLA photosensitive resins need to be cured by a chemical cross-linking reaction triggered by UV light, so the performance of the printed material is largely determined by the chemical reaction itself, such as print speed and print shrinkage. A good 3D printing design needs to be able to take into account all these systematic errors related to the nature of the material and process in advance, so that the best execution of 3D printing can be achieved.

The 3D printing Imported White Resin material can be used in the SLA 3D Printing forming process to manufacture parts that are not limited by geometric shapes, shorten the product development and manufacturing cycle, and can quickly and efficiently manufacture small batches of complex parts.

The Advantages Of 3D Printing Imported White Resin

Imported white resin with a shrinkage bottom and less dimensional change. 9900 resin is a low viscosity liquid photosensitive resin developed by DSM in the Netherlands to make strong, hard, water resistant functional parts. Parts made from 9900 resin material are opaque white in colour and resemble engineering plastics. 9900 resin material provides similar performance to traditional engineering plastics including ABS and PBT etc.The market price of imported white resin 9900 is around 0.85-1 yuan/g, and there are also preferential prices for large customers for large printing quantities, welcome to consult the customer service staff on the official website for details.

- Smooth surface of printed models

- High precision

- Water and moisture resistant

- Fast delivery times

- This material is USP Class VI and ISO10993 certified and can be used as a tool for auxiliary medical devices etc.

- Printed models can be post-treated with painting, silk-screening, plating etc.

The Case Studies Gallery Of Imported White Resin 3D Printing

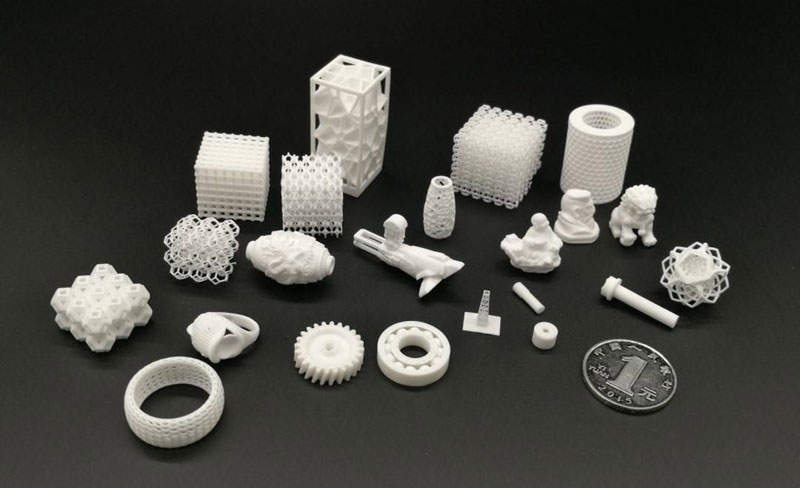

Due to the fluidic nature of the resin and the precision of the laser, the surface of the print often has a high degree of smoothness and is often used as a cosmetic verification part. The diagram below shows some examples of this resin material being used for the verification of the appearance of hand boards. The imported white resin also performs well when producing such highly complex prints, with a very fresh and smooth structure.

The Characteristics Comparison Of Imported White Resin

In addition to the outstanding performance of the printed form, many customers have different requirements for the application scenarios of their workpieces, which place new demands on the physical properties of the printed material, such as tensile strength, thermal deformation temperature and impact lightness, which are often of interest. The following material properties table will provide you with data to support your engineers or technicians. Of course, you can also use our customer service for information on materials.

| Performance | standard test | unit | value |

|---|---|---|---|

| Viscosity | cps @ 3o”c | 340 | |

| Critical Exposure | mJ/cm2 | 6.4 | |

| Young’s modulus | ASTM D638 | MPa | 2.51 |

| Tensile strength | ASTM D638 | MPa | 47 |

| Elongation | ASTM D638 | 7.50% | |

| Notched Impact Strength | ASTM D256 | J/m | 26 |

| Heat deflection temperature @0.46 Mpa | ASTM D648 | ℃ | 46″ |

| Heat deflection temperature @1.81Mpa | ASTM D648 | ℃ | 41″ |

Wonder Tech Is Committed To Providing You With The Most Comprehensive Range Of Materials Available, To Getting You The Best Discounts While Maintaining Quality, And To Choosing The Best Match For Your Material Printing Solution.