Realize the precision forming of aluminum alloy parts, the overall size consistency is good, the processing cycle is short, which is conducive to the rapid verification of new products; the…

3D Printing For Automotive Industries

3D printing technology has been applied to all aspects of automotive development and modification (concept design, model cars, prototypes, ……), the supply of automotive components (mirrors, instrument panels, air conditioning components, lamp components, ……), as well as tooling and production jigs for the automotive production process. It helps automotive engineers and designers to carry out comprehensive design evaluations before the production of components, and also helps companies to significantly reduce development costs and time-to-market.

The automotive industry uses 3D printing technology, including tooling, end-use parts and functional prototyping, to streamline production cycles, reduce the weight of automotive manufacturing tools and reduce production costs for many automotive exterior components, including bumpers, fenders, lights and car logos.

The ability to print a wide range of materials with different mechanical properties in a single pass has been widely used by manufacturers in the design and evaluation of automotive interior components during the development phase. Parts made up of a variety of materials and processes, including instrument panels, air conditioning exhaust fans, steering wheels, car levers and more, can be prototyped using 3D printing. On the one hand, it can reduce design costs compared to traditional manufacturing methods; on the other hand, it can accurately restore the shape and material properties of the product, so that all aspects can be evaluated and quickly modified, thus speeding up the time to market.

Wonder Tech is a comprehensive 3D printing manufacturer that integrates corporate personalised design specialising in the production of automotive interior modifications. With a professional modelling and design team, advanced 3D scanners and industrial grade 3D printers, Wonder Tech uses 3D-enabled digital development to traditionally address the shortcomings of manual production, allowing customers to experience a more intimate product service in terms of modelling to meet any customer’s requirements. Personalised and customised to show the owner’s personality and charm, welcome to call us for more information.

We Provide World-class Automotive 3D Printing Services

Wonder Tech is dedicated to providing game-changing solutions- high-performance solutions and faster Automotive 3D Printing services with flexible designs.

We have brought nearly 20 years of materials and manufacturing expertise to every layer of your 3D products to help you in unlocking every dimension of 3D printing techniques.

In addition to saving you production costs due to scale production, Wonder Tech’s small batch service also saves you time in getting your product to market, opening up a new sales model that allows you to get feedback from the market on your product in the shortest possible time, helping you to develop your product strategy.

Using 3D printing technology, concept models can be built in a matter of hours or days, helping garage and component modification manufacturers to optimise their designs and speed up the quality of their products. The proof of concept process. Wonder Tech3D printing creative design provides a one-stop 3D modelling and printing service, you are welcome to call us if you want to carry out car exterior modification.

Wonder Tech’s Case Studies On Automotive 3D Printing

With two decades of offering on-demand production and rapid prototyping services, Wonder Tech is the perfect partner for bringing ideas to life. We have a wide range of processes and materials to choose from, each with its own benefits and applications.If you have this requirement, please contact our professional team at [email protected] or contact us by visiting our website, we will provide you with a quote for free for the first time. Upload a model and we’ll do the rest!

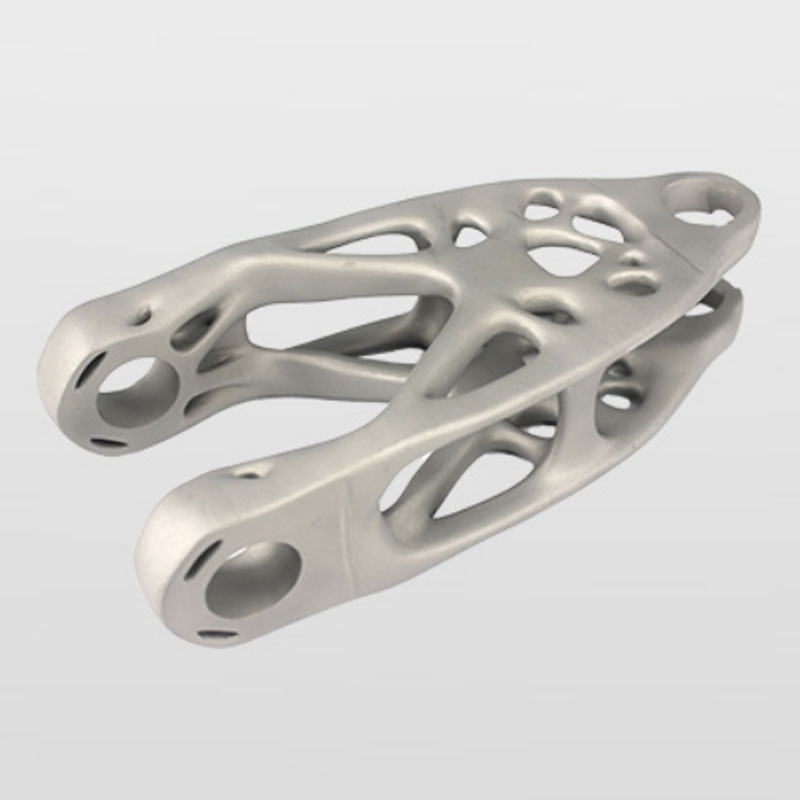

3D Printing Automotive Rocker

3D Printing Automotive Rocker realizes the precision forming of high-strength steel parts, and 3D printing integrated forming, which reduces the weight by 23% compared with the original design; no post-processing…

3D Printing Engine Outlet Pipe

3D Printing Engine Outlet Pipe Short production cycle: the processing time is reduced by half through 3D printing integrated molding,…

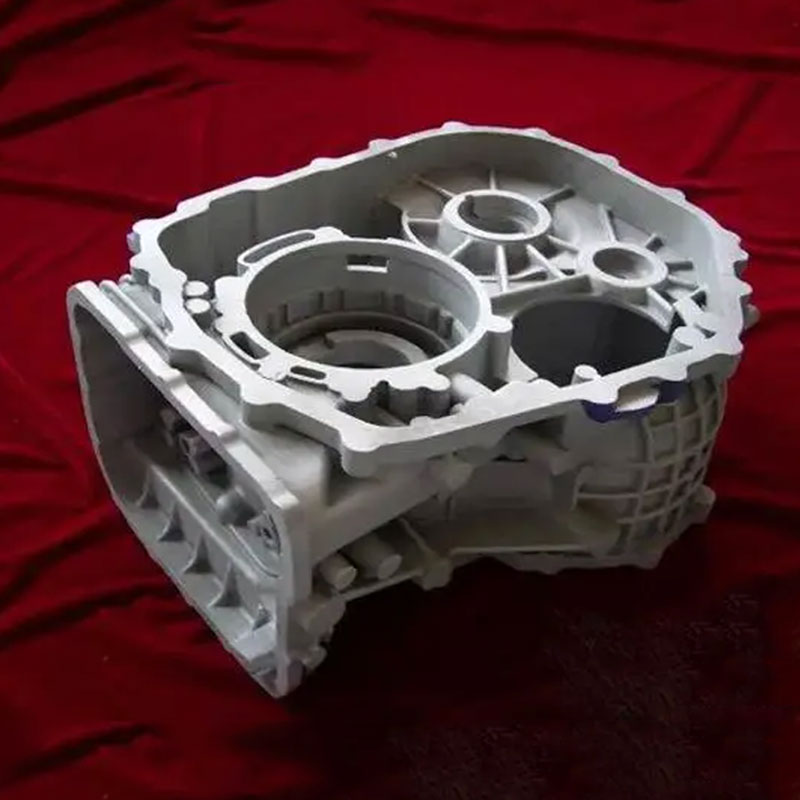

3D Printing Automobile Gearbox Housing

It should be said that it is impossible to realize such a design by CNC material reduction processing after the traditional casting is completed. Wonder Tech is aimed at using…

3D Printed Automobile Engine Block

Making medical implants is a relatively difficult job, involving knowledge of multiple disciplines such as medicine, biology, and materials science. …

3D Scanning And Printing Modified Motorcycle Model

This is not the first time BMW has entered into a relationship with 3D printing, 3D scanning technology. A few months ago, they used the technology to build thumb supports…

3D Scanning For Automotive Surface Data

A high-precision hand-held 3D scanner is used to obtain data on the vehicle’s curved surface to create the modified parts to ensure a precise and seamless fit.

Classic Car Reverse Design And Repair Service

Discontinued vehicles, classic cars repaired without parts, without drawings or moulds we will scan and reverse 3D print brand new parts specifically for you.

The Design And Modified Of Automotive Interiors And Exteriors

Through detailed design and communication with the owner of the modified vehicle, we can customise the vehicle modification programme.

We create customised conversion parts with design drawings to produce great results and cool looking vehicle conversion parts.

Manufacturing Complex Items Does Not Increase Cost

As far as traditional manufacturing is concerned, the more complex the shape of an object, the higher the manufacturing cost. For 3D printers, the cost of manufacturing complex-shaped items does not increase, and manufacturing a gorgeous complex-shaped item does not consume more time, skill or cost than printing a simple block. Manufacturing complex items without adding cost will disrupt traditional pricing models and change the way we calculate manufacturing costs.

Product Diversification Does Not Increase Costs

A 3D printer can print many shapes, it can be like a craftsman to make items of different shapes every time. Traditional manufacturing equipment has fewer functions and can make a limited variety of shapes. 3D printing saves the cost of training mechanics or purchasing new equipment. A 3D printer only needs a different digital design blueprint and a new batch of raw materials.

No Assembly Required

3D printing can make parts integrally formed. While traditional mass production was based on assembly lines, in modern factories machines produce identical parts that are then assembled by robots or workers (even across continents). The more parts a product has, the more time and cost it takes to assemble. 3D printers can print a door and its supporting hinges at the same time through layered manufacturing, without assembly. Omitting assembly shortens the supply chain, saving money on labor and shipping. The shorter the supply chain, the less pollution there is.

Fast Delivery

3D printers can print on demand. Just-in-time production reduces the physical inventory of enterprises, and enterprises can use 3D printers to manufacture special or customized products according to customer orders to meet customer needs, so new business models will become possible. Zero-time-delivery production minimizes the cost of long-distance transportation if the things people want are produced close to where they are needed.

Unlimited Design Space

Traditional manufacturing techniques and craftsmen make products with limited shapes, and the ability to make shapes is limited by the tools used. For example, traditional wooden lathes can only make round objects, rolling mills can only process parts assembled with milling cutters, and pattern-making machines can only create molded shapes. 3D printers can break through these limitations, opening up a huge design space, and even making shapes that currently may only exist in nature.

Zero-Skill Manufacturing

Traditional craftsmen need several years of apprenticeship to master the required skills. Mass production and computer-controlled manufacturing machines have reduced skill requirements, yet traditional manufacturing machines still require skilled professionals for machine adjustment and calibration. 3D printers obtain various instructions from design files, and to do the same complex items, 3D printers require less operational skills than injection molding machines. Unskilled manufacturing opens up new business models and enables new ways for people to produce in remote environments or in extreme situations.

Does Not Take Up Space, Portable Manufacturing

In terms of unit production space, compared with traditional manufacturing machines, 3D printers have stronger manufacturing capabilities. For example, an injection molding machine can only make objects much smaller than itself, whereas a 3D printer can make objects as large as its print bed. After the 3D printer is debugged, the printing equipment can move freely, and the printer can manufacture objects larger than itself. High throughput per unit space makes 3D printers suitable for home or office use because they require little physical space.

Reduce Waste By-Products

3D printers create metal with fewer by-products than traditional metal fabrication techniques. The waste of traditional metal processing is staggering, with 90% of raw metal being discarded on the factory floor. 3D printing creates less waste when making metal. With the advancement of printing materials, “net shape” manufacturing may become a more environmentally friendly processing method.

Unlimited Combinations Of Materials

Combining different raw materials into a single product is difficult for today’s manufacturing machines, which cannot easily fuse multiple raw materials together during cutting or molding. With the development of multi-material 3D printing technology, we have the ability to fuse different raw materials together. The mixing of previously unmixable raw materials creates new materials that come in a wide variety of shades and have unique properties or functions.

Exact Entity Replication

Digital music files can be copied endlessly without loss of audio quality. In the future, 3D printing will extend digital precision to the physical world. Together, scanning technology and 3D printing will increase the resolution of morphological transitions between the physical and digital worlds, allowing us to scan, edit and reproduce physical objects, creating exact copies or optimizing the original.