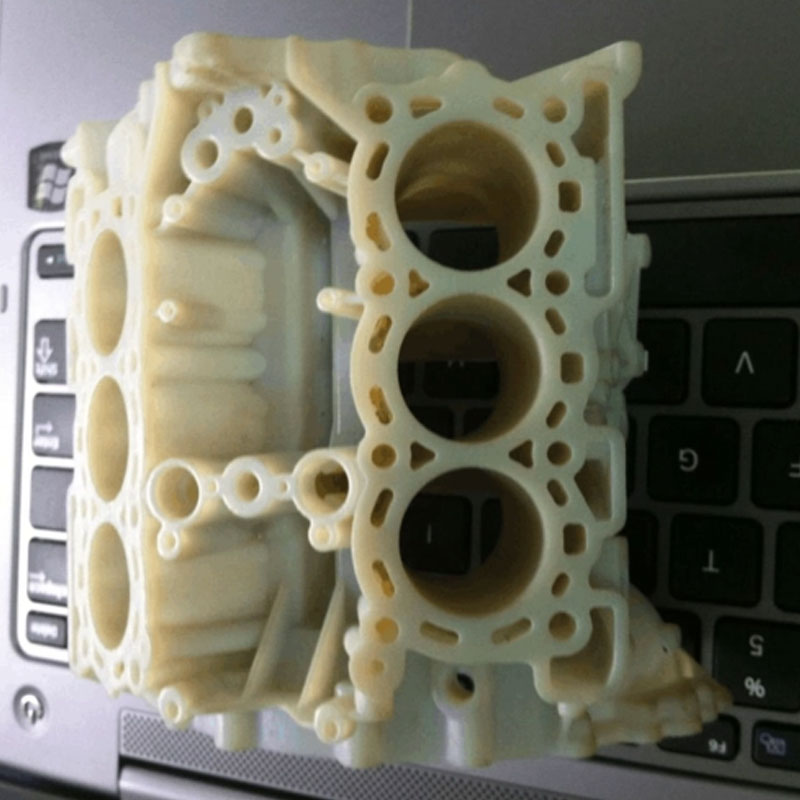

Engine Block

- – Material: Nickel-Titanium Alloy

- – Accuracy: 0.2mm

- – Process: Metal 3D Printing

- – Finlishing: Custom

- – Process: SLM 3D Printing

- – Easy to clean and maintain

- – High brightness and good appearance

- – Excellent quality and toughness

- – Great performance and durability

The fabrication of 3D printed products is based on the design files. There are some details and features that always need to be taken into account when designing a 3D printing part, but the best result varies depending on the different 3D printing services.Wonder Tech have a wide range of process and materials to choose from, each with its own benefits and applications.

Specifications

Parameter

Material

In industrial production, the automobile engine block is the heart of the automobile engine and is generally made of gray cast iron.

The cylindrical cavity in the upper part of the common cylinder block is called the cylinder, and the lower part is the crankcase supporting the crankshaft. Its inner cavity is the space for the crankshaft to move. Among them, many reinforcing ribs, cooling water jacket and lubricating oil are cast inside the cylinder. Road, etc., therefore, the structure of the cylinder is complex, the product size requirements are high, the wall thickness is within the range of 5-7mm, and the sand core of the water jacket of the cylinder is only 4mm wide, which makes casting difficult.

At present, this type of cylinder body generally adopts the casting process of boxless core assembly, and the molding materials generally used are divided into triethylamine cold core sand, furan resin sand, pipe resin sand, and coated sand. Due to the different modeling materials, the core making method is divided into manual core making and core making machine core. In the traditional process, the cylinder block has crankcase sand cores, front and rear end sand cores, cover cores, water jacket cores, tappet cores, oil passages, water passage cores, etc. After assembling these sand cores into one body, pouring molten iron and cooling to obtain Cylinder block blanks, among them, in the process of core assembly, special fixtures are generally used in combination with manual measurement to control the accuracy of core assembly.

However, the following problems also exist in the traditional process: such a core making and molding process produces a large number of sand cores, the core assembly method is complicated, the process control requirements are cumbersome, and the skill level of the on-site workers is high; at the same time, due to the The size of medium-sized products is difficult to control, resulting in large size errors. Therefore, in the prior art, due to the influence of these factors, castings are often scrapped due to reasons such as unqualified dimensions, and the scrap rate is as high as 30%. More than 20,000 US dollars, the cost of product trial production is very high, and the production verification cycle is as long as 4-5 weeks, which is not conducive to the development of new products. Therefore, how to design a core assembly molding process that produces high-quality and low-rejection castings, reduces the difficulty of core assembly molding, is simple to operate, and shortens the production cycle has become a technical problem that needs to be solved urgently.

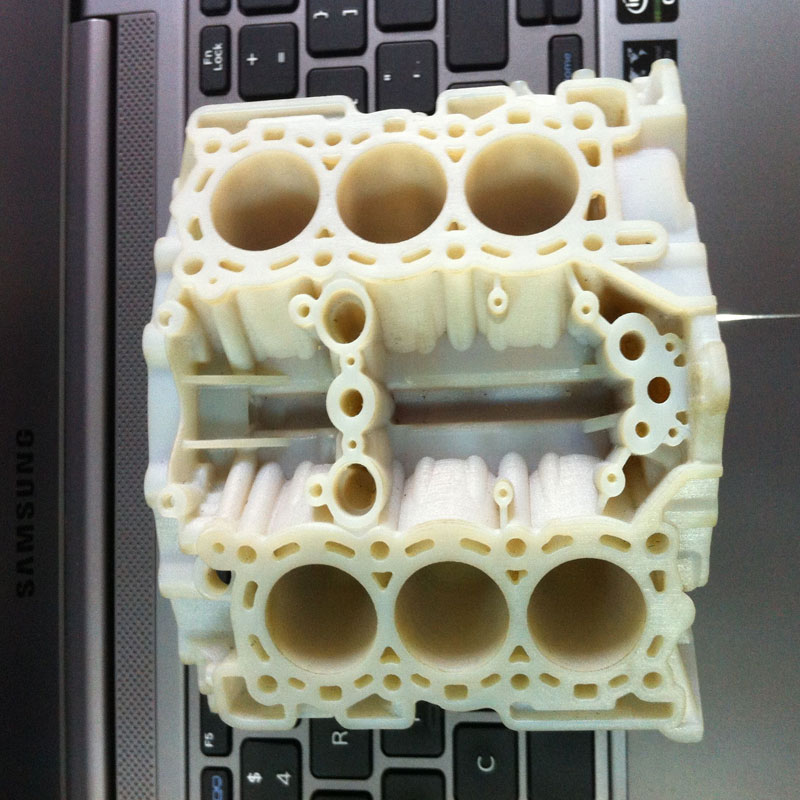

Traditional Crafts

- Weight: 5095g

- Cooling surface: 823 cm

3D Printing Process

- Weight: 1919g

- Cooling surface: 10233 cm2

Application Result

- Increased part performance and complexity

- Shorten development cycle

- Save materials and reduce R&D costs

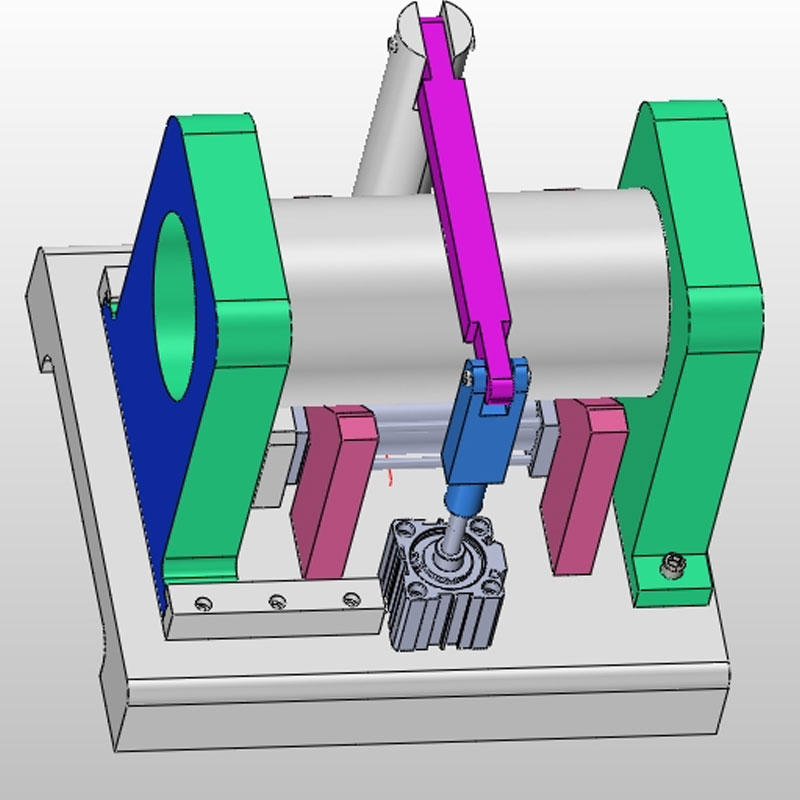

The invention belongs to the field of manufacturing automotive engine cylinder block castings, and in particular relates to a 3D printing production method for an automotive engine cylinder block. The method includes the following steps:

- Gating system design: According to the design principles of the gating system, an open pouring system is adopted;

- Sand core design: first, draw a complete mold in 3D software; then, divide the core from three directions: the cylinder mouth surface, the top position of the water jacket and the flange surface;

- Core molding method: core the sub-cores in turn, perform overall core assembly, and then cast.

The present invention designs a set of core assembly molding process suitable for such castings by adopting 3D printing technology, thereby reducing the casting rejection rate and the difficulty of core assembly modeling of cylinder castings, achieving high quality and low rejection rate The purpose of castings, as well as simplifying process control, reducing the cost of new product development, and speeding up the progress of trial production.

World-Class 3D Printed Automobile Engine Block Services

Wonder Tech is dedicated to providing game-changing solutions- high-performance solutions and faster 3D Printed Automobile Engine Block services with flexible designs.

We have brought nearly 20 years of materials and manufacturing expertise to every layer of your 3D products to help you in unlocking every dimension of 3D printing techniques.

3D Printing Technology And Material Table

At present, the commonly used 3D printing technologies include Multi Jet Fusion(MJF), Selected Laser Sintering(SLS), Stereolithography(SLA), Fused Deposition Modeling (FDM), and Direct metal laser sintering (DMLS).

| Cumulative Technology | Basic Material |

| Fused Deposition Modeling (FDM) | Thermoplastics, eutectic system metals, edible materials |

| Electronic Beam Freeform Fabrication (EBF) | Almost any alloy |

| Direct Metal Laser Sintering (DMLS) | Almost any alloy |

| Electron Beam Melting (EBM) | Titanium alloy |

| Selective Laser Melting (SLM) | Titanium alloy, cobalt chromium alloy, stainless steel, aluminum |

| Selective Heat Sintering (SHS) | Thermoplastic powder |

| Selective Laser Sintering (SLS) | Thermoplastic, metal powder, ceramic powder |

| Polypropylene (PP) | plaster |

| Laminated Object Manufacturing (LOM) | Paper, metal film, plastic film |

| Stereolithography (SLA) | Light hardening resin |

| Digital Light Processing (DLP) | Light hardening resin |

Our Quality Promise

Have an idea? have a napkin sketch? From proof of concept to functional tools for the manufacturing floor, 3-di.com has multiple 3D printing technologies at our disposal to help you bring your design to life. Contact us today!Send your files to reiceve a quote. Accepted file types: Hi-Res .stl, .sldprt. .step, .jpg, .pdfInspection reports included with every orderAccuracy up to 0.01mm, maximum size 1500mm100% visual inspection for every part Highly vetted 3D printing partnersMaterial certifications availableQuality guaranteed. If your parts aren’t made to spec, we’ll make it right.Over 100 machines running 24 hours a dayMore than 60 experienced masters

3D Printing Part Sizes

| FDM | 200 x 200 x 200 mm for desktop printers, up to 900 x 600 x 900 mm for industrial printers |

| SLA | 145 x 145 x 175 mm for desktop printers, up to 1500 x 750 x 500 mm for industrial printers |

| SLS | 300 x 300 x 300 mm, up to 750 x 550 x 550 mm |

| DMLS/SLM | 250 x 150 x 150 mm, up to 500 x 280 x 360 mm |

| MJF | 380 x 285 x 380 mm |

Dimensional Accuracy In 3D Printing

The dimensional accuracy refers to how accurate the size and form of the printed part are compared to that in the CAD design. Factors that affect dimensional accuracy include material quality, equipment, post-processing, and more. Dimensional tolerance, shrinkage, and support requirements are three key elements to measuring dimensional accuracy. Below are the dimensional tolerance of different 3D processes.

| FDM dimensional tolerance | prototyping (desktop):±0.5% (lower limit:±0.5 mm), industrial:±0.15% (lower limit:±0.2 mm) |

| SLA dimensional tolerance | prototyping (desktop):±0.5% (lower limit:±0.10 mm) industrial:±0.15% (lower limit:±0.01 mm) |

| SLS/MJF dimensional tolerance | ±0.3% (lower limit:±0.3 mm) |

Layer Height In 3D Printing

Layer height is a measurement of the amount of material extruded by the printer’s nozzle for each layer of your part. It is measured in microns or millimeters. The selection of layer height is important for some 3D printing technologies, such as SLA and FDM. Below are the typically applied layer height for different processes.

- – FDM: 50 – 400 μm

- – SLA: 25 – 100 μm

- – SLS: 80 – 120 μm

- – MJF: 80 μm

- – DMLS/SLM: 30 – 50 μm

3D printing and prototyping have advanced development in recent years. With these improvements, metal 3D printing has become a possibility. Metal 3D printing is used in a variety of sectors. Companies that use metal 3D printing are discovering that 3D printing complicated metal parts in low quantities is considerably more cost-effective than traditional methods of production. Metal 3D printed items are cheaper and have a wider range of material alternatives. Aluminum is a popular metal for 3D printing since it is both sturdy and lightweight. Steel is another extensively used material that is perfect for industrial applications due to its strength, good polish, and temperature tolerance. Metal 3D printing is utilized in a wide range of sectors for a variety of purposes. Functional prototypes, end-use parts, Jigs, tooling, and fixtures are some of the applications.

| Metals | Applications |

|---|---|

| Stainless steel | Utensils, cookware, and other items that could ultimately come into contact with water |

| Bronze | Vases and other fixtures |

| Gold | Rings, earrings, bracelets, and necklaces |

| Nickel | Coins |

| Aluminum | Thin metal products |

| Titanium | Strong, solid fixtures |

3D Printing Plastic Materials Guide

Wonder Tech provides plastic 3D printing services with constantly high efficiency and quick turnaround. Advanced 3D printers and optimal materials allow us to ensure both cheap prices and premium quality.

| Plastics | Features | Applications |

|---|---|---|

| ABS | Tough, strong, durable, heat-resistant, cost-effective, flexible, reusable, not biodegradable | Car bodies, appliances, and mobile phone cases |

| PLA | Easy to work with, environmentally friendly, biodegradable, available in resin and filament with a variety of colors | Food packaging, biodegradable medical devices and implants |

| PVA | Water-soluble | Often use to create a support structure for portions of a product that may warp or collapse |

| PP | Affordable, chemical resistant, flammable, and degrades with UV light | Household containers, lab equipment, and textiles |

| Nylon/PA | Strong, lightweight, durable, heat and impact-resistant, but not resistant to strong acids and bases | Applications that require high mechanical properties and functional prototypes |

| PEI | Can withstand high heat | Injection mold tools and heat-resistant components |

| PC | Heat resistant up to 135 °C, durable, impact and shatter resistant, moderately flexible, transparent, electrically non-conductive | Prototype windows and other clear products |

| PMMA/Acrylic | Good impact strength, comparable clarity, and UV absorption properties | Automobile headlights, commercial aquariums and other alternatives to glass |

| CPVC | High heat distortion temperature, chemical inertness, dielectric, and flame and smoke properties | Chemical processing, power generation, semiconductor, wastewater treatment |

| PEEK | Wear-resistant, good weight-to-strength ratio, high thermomechanical properties | Medical custom-made implants, devices, aerospace and automotive parts |

| PETG | High impact resistance, excellent chemical and moisture resistance | Compliant mechanisms, water bottles, electronic enclosures |

| TPU | Flexible, abrasion-resistant, resistant to impacts and many chemicals | Sporting goods, aerospace and automotive |

| PETP/Ertalyte | High dimensional stability, mechanical strength, low moisture absorption, physiologically inert | Thin films, containers for liquid drinks |