If the human skeleton becomes spirally delaminated, the result is a spiral fracture (a fracture that occurs when a bone is subjected to torsional force). However, for crustacean exoskeletons, spiral layering is more of a deliberate functional design that makes their shells stiffer.

The exoskeletons of crustaceans such as shrimps shells, lobsters, and crabs are composed of chitin protein fibers that are layered in a spiral pattern, also known as a briggan structure.

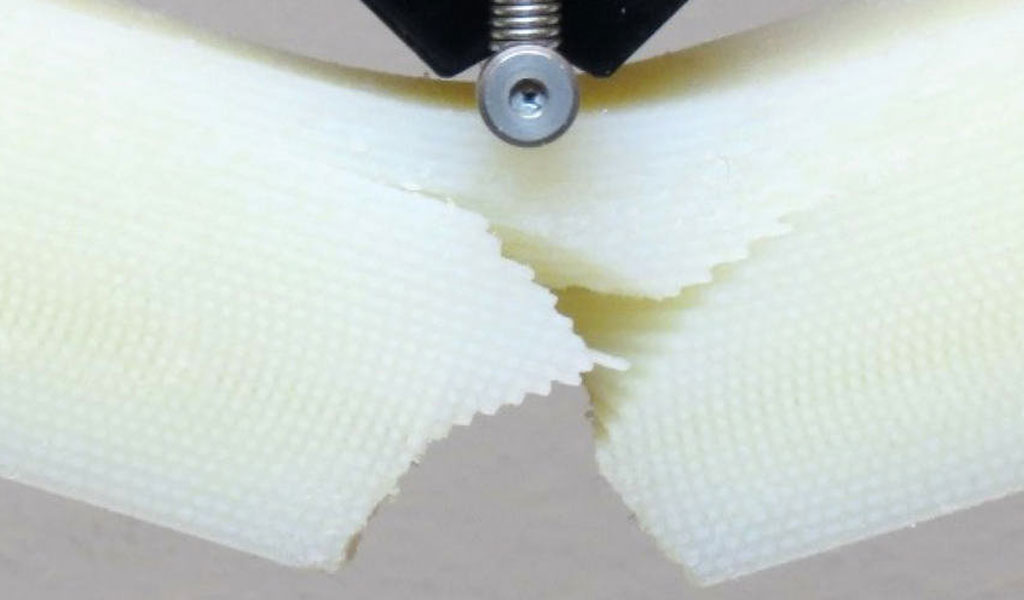

When their exoskeleton is impacted and cracks develop, the cracks don’t go straight through all the layers like a piece of wood. Instead, cracks spiral up through the structure in layers. “Rather than becoming a single large crack, the crack forms into many smaller cracks that absorb the energy of the impact,” the Purdue University researchers wrote.

A research team led by Pablo Zavattieri, a professor of engineering at Purdue University, has long studied crustacean shells and applied this structure to 3D printing and 3D Modeling. After testing, the strength of the 3D printed parts with the addition of Brigan structure has been improved to a certain extent. Nature is indeed a good teacher for mankind.