| Category | Type | Category | Type |

|---|---|---|---|

| Printing devices | Wiiboox SLM280/150 etc. | Maximum Build Size | 280 x 280 x 350MM |

| Printed material | Titanium Alloys | Standard delivery time | 4-10 working days |

| Aluminum Alloys | Dimensional Accuracy | ±0.06% with a lower limit of ±0.2MM | |

| stainless Steel | Storey height | 0.035MM |

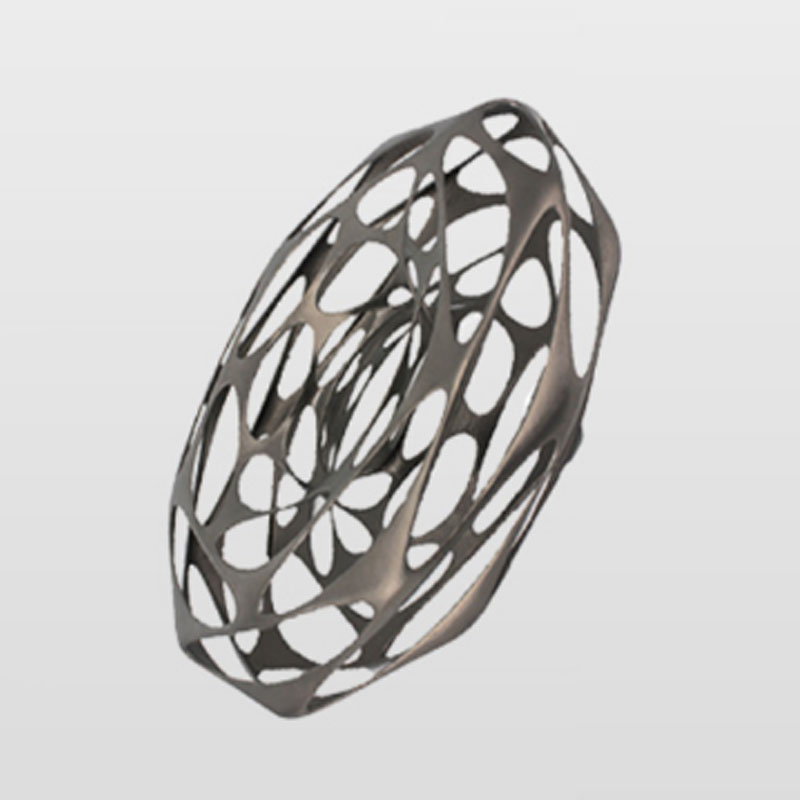

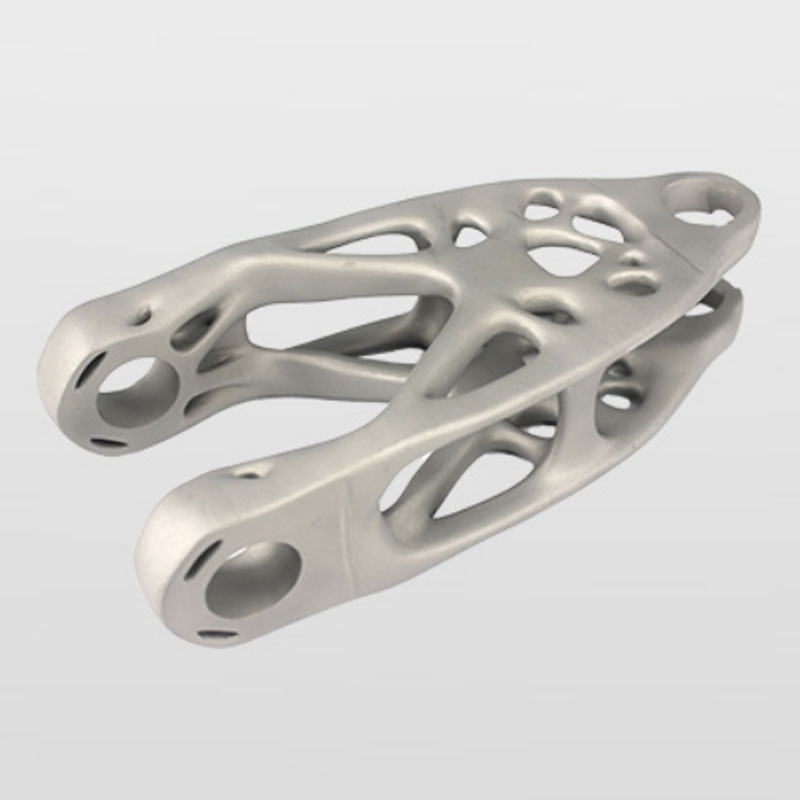

SLM 3D Printing Services

SLM 3D Printing is selective laser melting, in which a laser is used to completely melt the powder during processing and cool it to shape, without the need for adhesives. The great design freedom and advanced material properties make it particularly suitable for high-end applications.

- dimensional accuracy of ± 0.06% with a lower limit of ± 0.2 mm.

- Parts are disassembled and de-supported.

- Surface grinding smooth and polished.

Wonder Tech is ISO9001-2015 certified and provides high-quality SLM 3D Printing services for manufacturing companies across a wide range of industries.

As a company, we specialize in high-quality SLM 3D Printing parts, which allows us to create shapes with complex geometry and designs with a high degree of precision.

Ideal for rapid prototyping and small-scale production, high-quality SLM 3D Printing is perfect for customers that need high-quality on-demand parts and components quickly.

Thanks to our online SLM service, you can have access to professional 3D printers for prototyping and production, distantly, and without needing to worry about operating the machines yourself. You’ll get your 3D printed metal parts, fully functional and ready to be used or integrated into a larger object, within a few days.

To learn more about Wonder FDM 3D Printing capabilities, contact us or upload your files, get an immediate quote and be ready for manufacturing in less than 5 minutes!

SLM 3D Printing Parts And Components

Using this technique, we turn powder into different parts by scanning, 3d modeling, printing, and designing. Every powder block can be transformed into many different forms. However, we carefully select the materials. We used high-end 3d printing material and more. According to your exact specifications, we guarantee high-precision slm 3d printing parts.

The Compare Material Properties Of SLM 3D Printing

20 μm = high resolution (HR)

30, 40, and 60 μm = normal resolution (NR)

| Materials | Resolution | Condition | Ultimate Tensile Strength (ksi) | Yield Stress (ksi) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 199 | 178 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 198 | 179 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 82 | 56 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 85 | 55 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 39 | 26 | 15 | 42 HRB |

| 30 μm | Stress Relieved | 50 | 33 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 43 | 27 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 182 | 112 | 17 | 39 HRC |

| 30 μm | As Built | 176 | 119 | 14 | 38 HRC | |

| Inconel 718 | 20 μm | Stress Relieved | 143 | 98 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 144 | 91 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 208 | 175 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 139 | 83 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 201 | 174 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 153 | 138 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 144 | 124 | 18 | 33 HRC |