3D printed titanium alloy pen. The material used is titanium alloy. The flowers are integrally formed with a hollow design, with exquisite design and exquisite workmanship. The surface of the pen body is composed of a world map and the words “in the world, in Xi’an” in multiple languages, with a delicate texture. Read more

Fymicohuang Posts

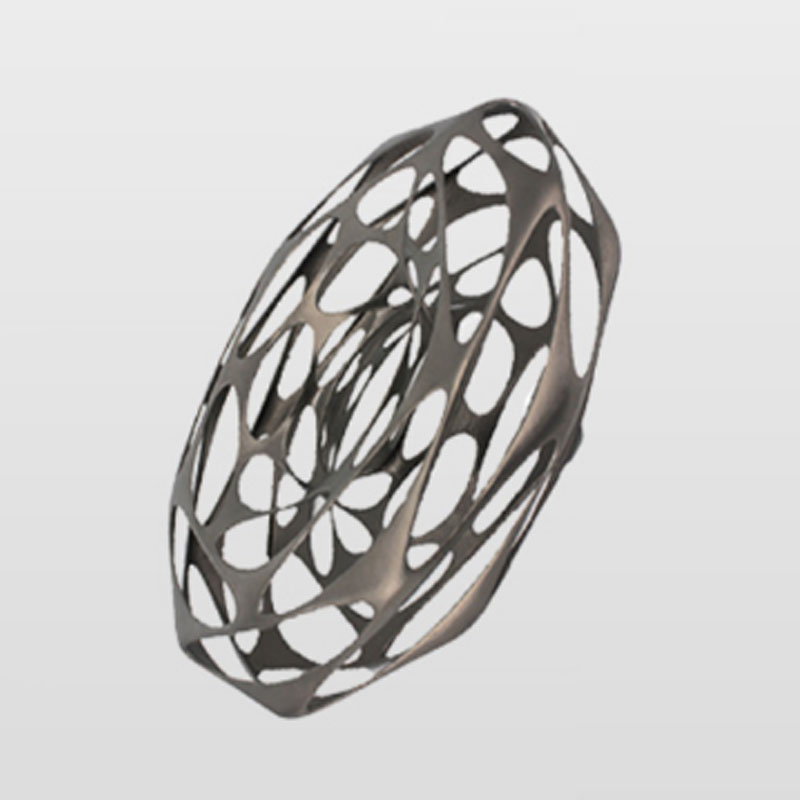

3D printed titanium alloy lampshade. The integrated manufacturing of thin-walled, large-sized, hollowed-out and special-shaped curved surface structures has been realized. The process performance is stable, the surface quality is high, and the space is beautifully shaped. Read more

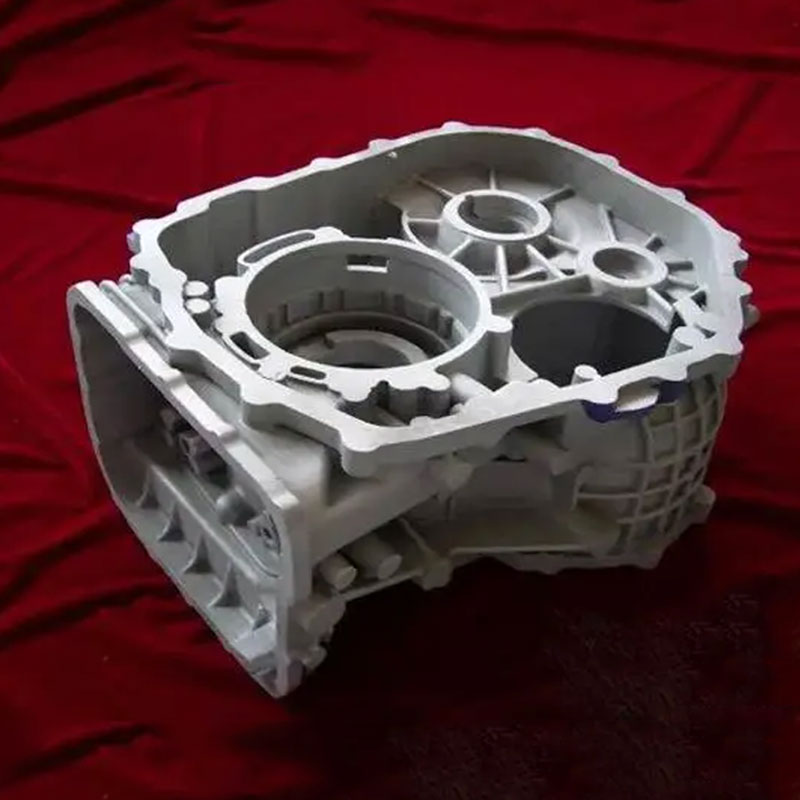

Realize the precision forming of aluminum alloy parts, the overall size consistency is good, the processing cycle is short, which is conducive to the rapid verification of new products; the batch of key parts of high-end equipment is small, the cost of mold opening is high, and the production cycle is long. Read more

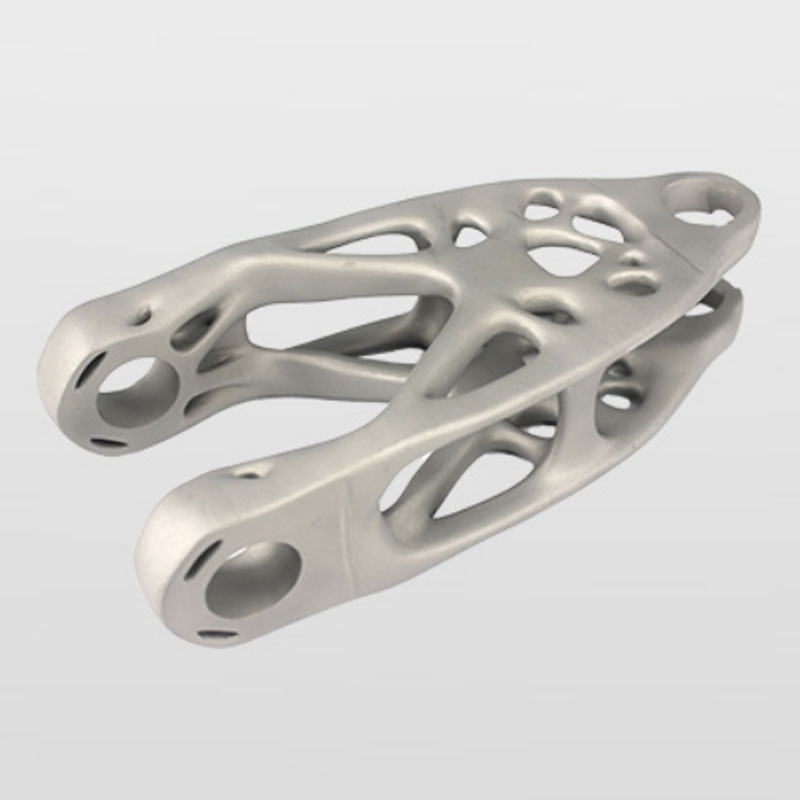

3D Printing Automotive Rocker realizes the precision forming of high-strength steel parts, and 3D printing integrated forming, which reduces the weight by 23% compared with the original design; no post-processing is required, and the manufacturing cycle is shortened by 50%-70%. Read more

This structure adopts arc additive manufacturing technology: (WAAM) one-time overall preparation and forming, the structure is a spatial topology structure, the spatial envelope size is 550550900mm, and the minimum hanging angle of the structural branches is 65. 2. Read more

3D Printing Engine Outlet Pipe Short production cycle: the processing time is reduced by half through 3D printing integrated molding, Read more

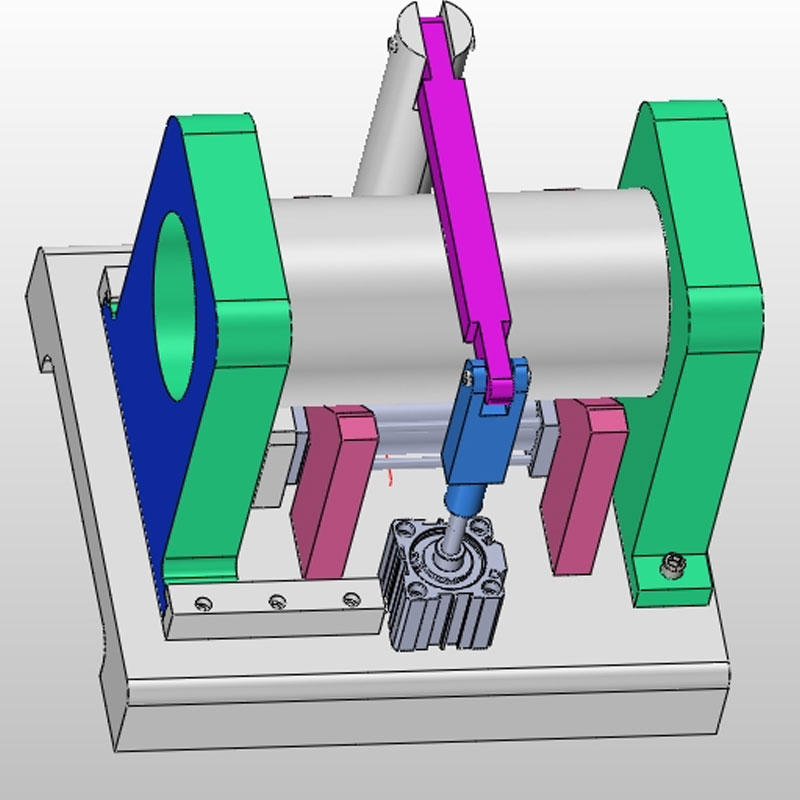

Laser selective melting additive manufacturing technology is mainly used for the integrated near-net forming of small and medium-sized complex metal components, such as engine parts, integrated rudder wings, pipeline valves, lattice sleeves and other products, and can also be used for the preparation of advanced structures such as thermal insulation and impact resistance. Read more

It should be said that it is impossible to realize such a design by CNC material reduction processing after the traditional casting is completed. Wonder Tech is aimed at using the combination of reduced material manufacturing and added material manufacturing to manufacture lightweight shell with integrated heat exchange function, effectively realizing the combination of complexity and precision. Read more

Making medical implants is a relatively difficult job, involving knowledge of multiple disciplines such as medicine, biology, and materials science. Read more