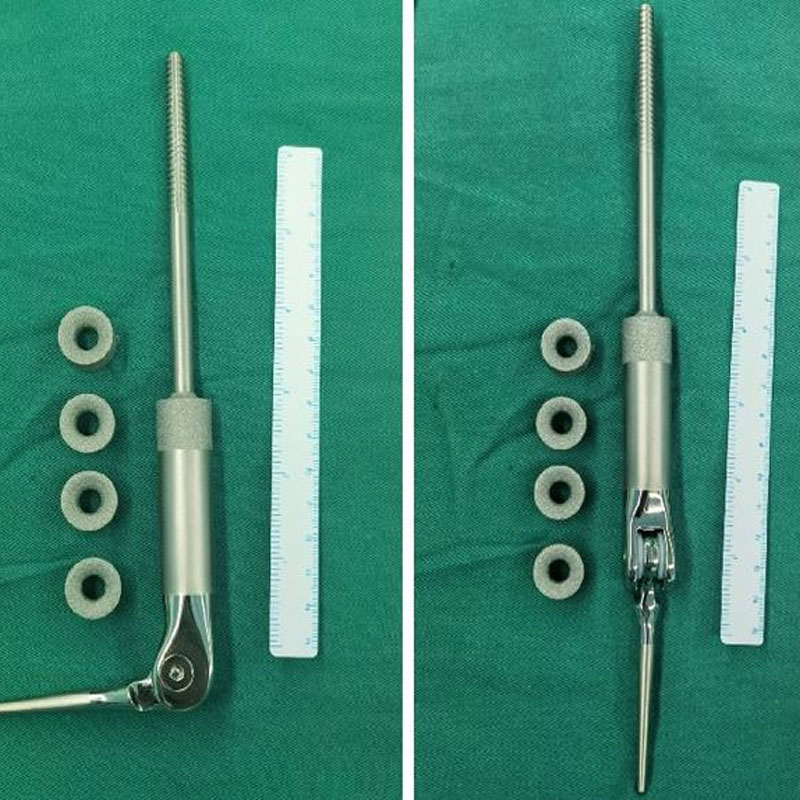

Making medical implants is a relatively difficult job, involving knowledge of multiple disciplines such as medicine, biology, and materials science. Read more

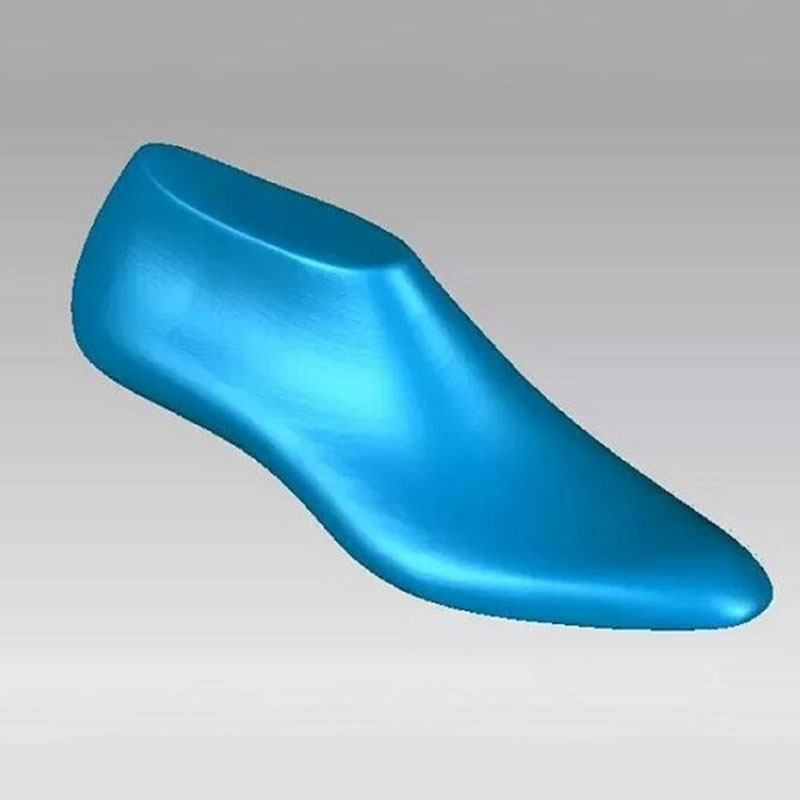

The sole mold is a kind of tool used to make or copy the finished shoe sole, and its manufacturing cycle and quality will affect the competitiveness and replacement of the product in the market. Inject 3D scanning and 3D printing technology into the field of shoe sole mold production, truly realize the process optimization of shoe mold production and speed up product optimization iterations. Read more

This is not the first time BMW has entered into a relationship with 3D printing, 3D scanning technology. A few months ago, they used the technology to build thumb supports for workers to relieve repetitive motion stress on their joints while assembling and finishing BMW vehicles. The type of stress relief in the latest project involving 3D printing isn’t all that important to BMW’s workers, but it isn’t to those interested in driving a super-smooth BMW R9T motorcycle. Read more

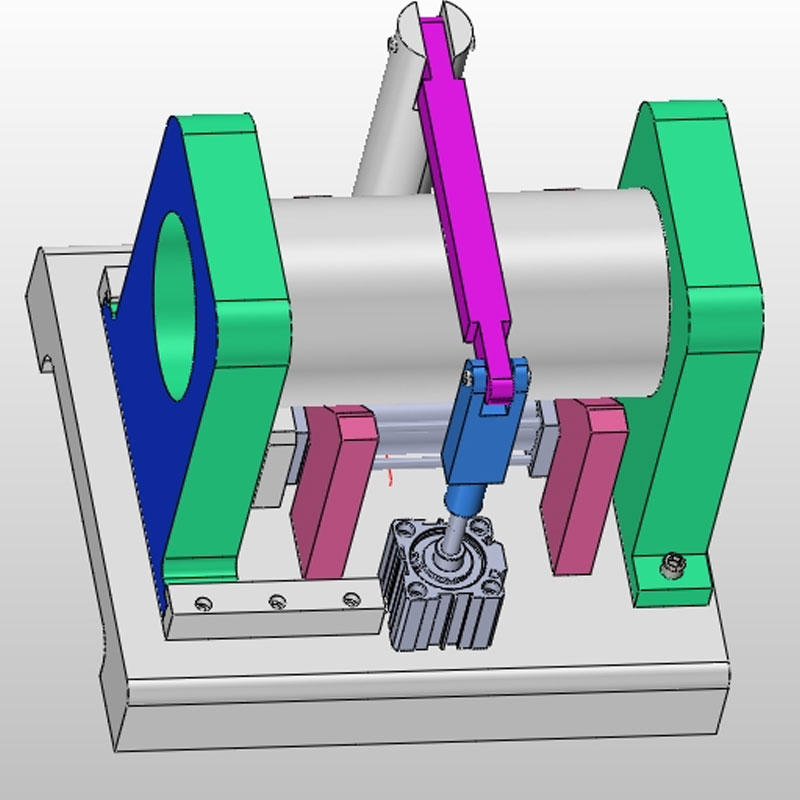

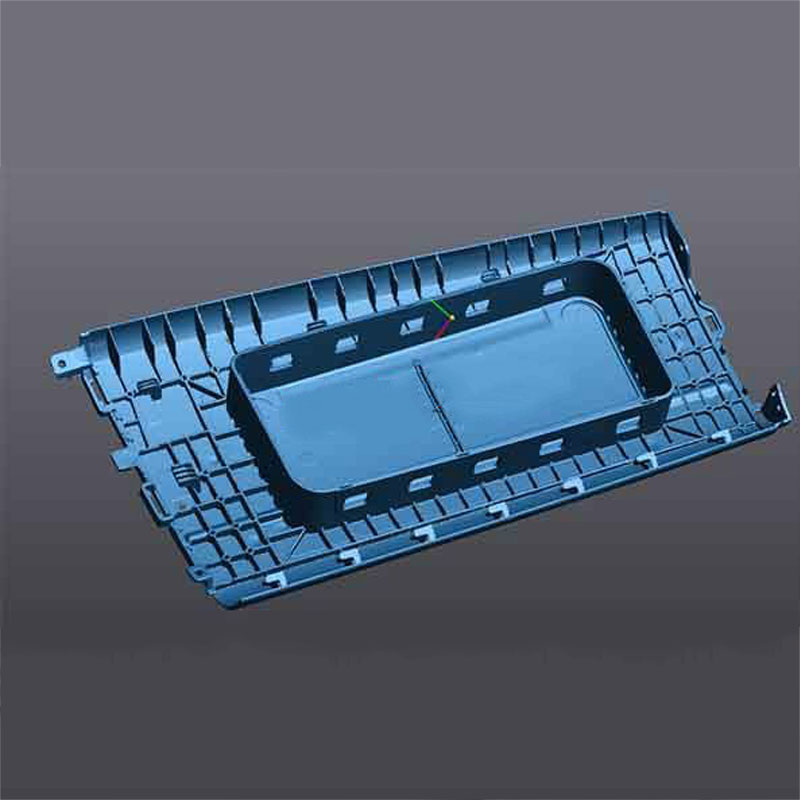

Car modification is not only favored by consumers in the direction of appearance, but also the demand for improving performance and practicality is also increasing. Being able to quickly and effectively modify the auto parts specified by customers is the pursuit of all car modification companies and engineers, and it is also the requirement of individualized and differentiated consumers in the future. Read more

In recent years, we have seen that 3D scanning technology has been used to help protect many of China’s cultural heritage. Now, let’s take a look at the handheld 3D scanner that created a very detailed 3D model of architectural landmarks on Buddhist sites, and recorded the process in the case study. Read more

An essential part of the process of modifying the exterior of a car is to obtain data on the car’s curves in order to create a perfect fit.There are three methods of obtaining car exterior data. Read more

Sculpture company wanted to equivalently scale down an existing sculpture and turn it into a scaled-down version as a souvenir. However, traditional sculptures are not available electronically and direct modelling is not possible to achieve exact equivalence. We therefore used the method of scanning first, using a high precision scanner to repair the model through specialist software and process it to a level suitable for printer production. Read more